Surplus industrial equipment can be a burden or an opportunity, depending on how it’s managed. In the industry, the rapid pace of technological advancements and evolving production requirements often lead to accumulating unused or outdated machinery and components. However, these surplus assets need not become mere relics of the past. Instead, they can be transformed into valuable resources that benefit your organization in various ways. This article explores innovative strategies to maximize surplus industrial equipment, from repurposing and recycling to reselling and donating. By harnessing the potential of these surplus assets, businesses can reduce waste, improve their financial bottom line, and contribute to sustainability goals.

Resell or Auction

Reselling or auctioning surplus industrial equipment is a practical and profitable way to maximize the value of assets your organization no longer needs. Doing so can recover some of your initial investment and generate funds for other projects or equipment purchases. Auctions in person or online offer a transparent and competitive platform for selling surplus equipment to the highest bidder. This method often yields fair market prices, especially if the equipment is in good working condition or has unique features. It also allows you to reach a broader audience of potential buyers.

Reselling through online marketplaces or industrial equipment dealers is another option. This approach provides flexibility in terms of pricing and negotiation, as well as the ability to connect with buyers who might be explicitly searching for the equipment you have available. Both methods require proper marketing and documentation to attract potential buyers effectively. Moreover, they can help your organization recoup valuable capital and ensure surplus industrial equipment finds a new purpose in industries still in demand.

Repurpose

Repurposing surplus industrial equipment by consignment services is a strategic way to maximize its value and extend its useful life. Instead of disposing of equipment that may no longer serve its original purpose, businesses can adapt and modify it for new applications. This approach not only saves money but also reduces waste and promotes sustainability.

Repurposing can involve various creative solutions. For example, conveyor belts can be transformed into workbenches, old machinery parts can become art installations and storage containers can be repurposed as modular office spaces. The key is to assess the equipment’s condition and identify ways it can be adapted to meet current operational needs.

Repurposing surplus equipment also allows for innovation and experimentation within an organization. It encourages employees to think outside the box and find novel uses for existing resources. Moreover, repurposed equipment often adds character and a unique touch to work environments, fostering a sense of creativity and resourcefulness among the workforce. Repurposing is an economically and environmentally sound strategy that can breathe new life into surplus industrial assets.

Lease or Rent

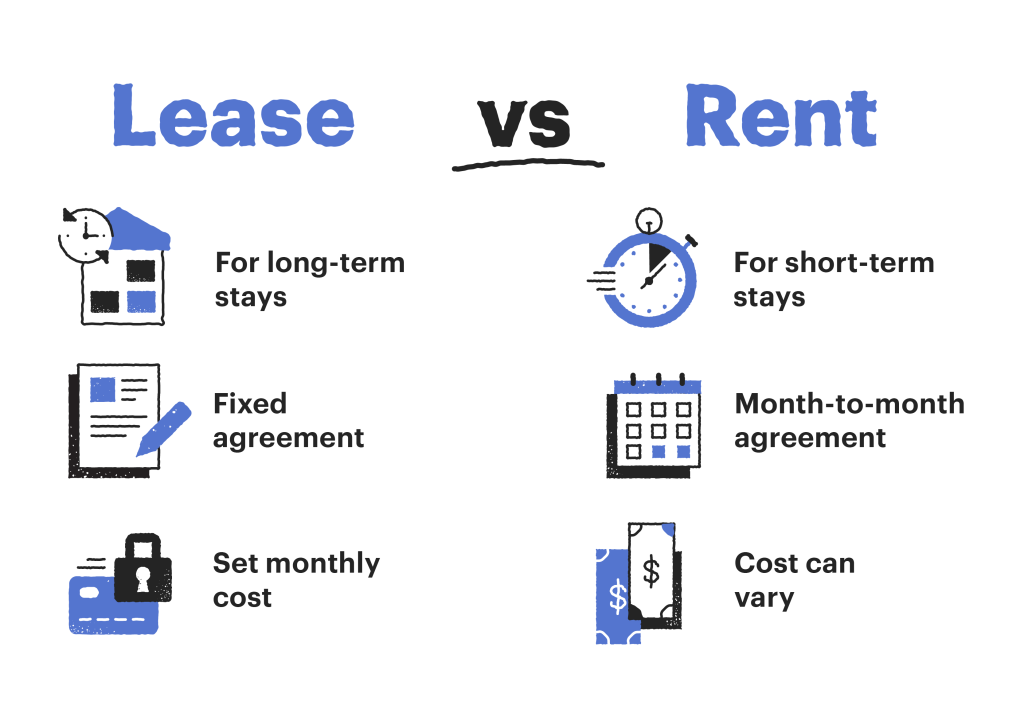

Leasing or renting surplus industrial equipment can be a strategic move for businesses looking to maximize the value of their excess assets. This approach enables organizations to generate revenue from equipment they no longer need while providing cost-effective solutions for other businesses.

You tap into a broader market of potential users by offering surplus equipment for lease or rent. Companies needing temporary equipment or minimizing upfront capital expenditure can benefit from this arrangement. This generates income and helps recoup some of the initial investment in the equipment.

Furthermore, leasing or renting can lead to long-term partnerships, as clients might return for additional equipment needs, fostering customer loyalty. It also keeps the surplus equipment well-maintained and in use, reducing the need for storage and potential depreciation. Leasing or renting surplus industrial equipment is a win-win strategy that optimizes resource allocation and supports sustainable business practices.

Donating

Donating surplus industrial equipment is a socially responsible and philanthropic way to utilize equipment your business no longer needs. By donating, you can benefit both your community and your organization. Here’s why:

Firstly, donating surplus industrial equipment can significantly impact local schools, nonprofit organizations, or community groups. They often operate with limited budgets and may need more resources to purchase expensive machinery. Your donation can help them fulfill their missions more effectively.

Secondly, it’s an excellent way to enhance your company’s reputation and foster goodwill within the community. Supporting local initiatives and organizations can build strong relationships and improve your brand image. Moreover, donating equipment reduces waste and contributes to environmental sustainability by extending the useful life of industrial machinery. It diverts equipment from landfills, reducing your ecological footprint.

Recycle

Recycling surplus industrial equipment is an eco-conscious approach that promotes sustainability and minimizes environmental impact. When machinery or equipment reaches the end of its operational life or becomes obsolete, recycling is a responsible way to manage its disposal.

The process typically involves dismantling the equipment to recover valuable metals, plastics, and other materials. These materials can then be repurposed for various applications, reducing the need for extracting and processing new resources. Recycling also helps divert electronic waste and potentially hazardous materials from landfills, preventing soil and water contamination.

Moreover, recycling surplus industrial equipment contributes to the circular economy, where resources are reused and repurposed, reducing the demand for raw materials and energy-intensive production processes. This conserves natural resources and reduces greenhouse gas emissions associated with manufacturing.

Training and Testing

One valuable way to utilize surplus industrial equipment is by employing it for training and testing. Surplus equipment can be invaluable for training new employees, offering them hands-on experience with machinery and processes in a controlled environment. This accelerates their learning curve and enhances their skill set, ultimately contributing to improved productivity. Moreover, surplus equipment can be instrumental in testing new technologies, processes, or modifications without disrupting primary production operations. It allows businesses to experiment and fine-tune their strategies, ensuring potential issues or inefficiencies are identified and resolved before implementing changes on a larger scale. Overall, leveraging surplus industrial equipment for training and testing maximizes its utility and promotes a culture of continuous improvement and innovation within the organization.

Spare Parts Inventory

Creating a spare parts inventory is a strategic approach to maximizing surplus industrial equipment. Instead of discarding or selling off functional components, such as motors, valves, or sensors, you can stockpile them as spare parts. This inventory is a valuable resource for minimizing downtime in your production process. When a critical component fails unexpectedly in your operational equipment, readily available surplus parts can significantly reduce the time required for repairs. It ensures that your machinery can be quickly restored to working condition, saving time and money while maintaining the efficiency of your industrial operations. By repurposing surplus equipment in this way, you optimize resource utilization and enhance your organization’s ability to respond swiftly to unforeseen maintenance needs, ultimately bolstering productivity and reliability.

Conclusion:

Surplus industrial equipment should be considered and carefully discarded. The multitude of options available for its utilization, from creating spare parts inventories to donating or recycling, can benefit organizations significantly. By embracing these strategies, businesses can minimize waste, lower operational costs, and contribute to a more sustainable industrial landscape, ultimately enhancing their competitiveness and environmental responsibility.