Introduction

Thermoforming is an efficient and cost-effective way to produce plastic parts for industries ranging from automotive and aerospace to medical and packaging. However, the success of thermoforming depends not just on material selection and forming efficiency—it also requires precision in tooling, trimming, and finishing.

Choosing the right mold materials, implementing high-accuracy trimming techniques, and applying finishing processes can make the difference between a flawless part and a costly defect. In this article, we’ll explore how to select the right tooling, ensure precise trimming, and apply finishing techniques that elevate thermoformed products to the highest quality standards.

1. Tooling for Thermoforming: Choosing the Right Mold for the Job

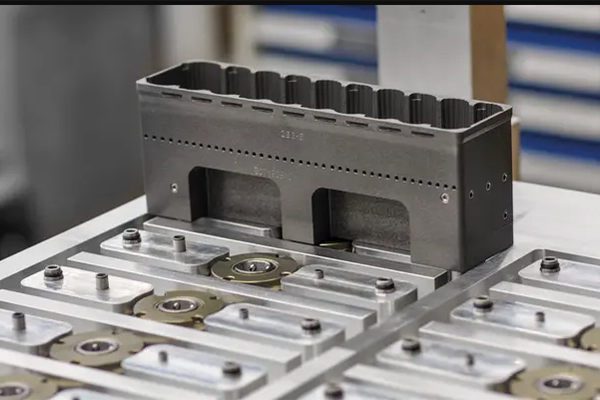

Molds are the foundation of thermoforming, determining part accuracy, surface finish, and production efficiency. The right mold material and manufacturing method directly impact cycle times, tool longevity, and product consistency.

1.1 Factors to Consider in Mold Selection

Before choosing a mold type, manufacturers must consider:

✔ Production Volume – Short-run molds can be made from wood or urethane, while high-volume production requires aluminum molds.

✔ Surface Finish Requirements – Polished aluminum molds are necessary for high-gloss or transparent parts, while textured molds provide matte or patterned surfaces.

✔ Feature Complexity – Machined molds offer superior detail, while cast molds are more cost-effective for large parts.

✔ Heat Transfer & Cycle Time – Aluminum molds dissipate heat efficiently, reducing cooling time and improving throughput.

1.2 Types of Thermoforming Molds

| Mold Type | Best For | Pros | Cons |

| 3D-Printed Molds | Prototyping, low-volume | Fast, cost-effective, complex geometries | Limited durability, rough surface finish |

| Machined Wood/MDF Molds | Prototyping, small runs | Low-cost, quick turnaround | Short lifespan, moisture-sensitive |

| Machined Urethane Foam Molds | Medium-run production | More durable than wood | Limited detail, matte finish |

| Aluminum-Filled Urethane Molds | Mid-volume production | Moderate durability, cost-effective | Not as long-lasting as full aluminum |

| Machined Aluminum Molds | High-precision, high-volume | Long lifespan, excellent detail | Higher initial cost |

| Cast Aluminum Molds | Large, high-volume production | More affordable for large molds, cooling integration | Less precise than machined aluminum |

1.3 Mold Surface Finishing: Enhancing Appearance and Functionality

The surface finish of the mold directly affects the final appearance and release properties of the thermoformed part.

- Polished Finish → Required for optically clear parts like PETG and polycarbonate.

- Textured/Matte Finish → Improves grip, hides imperfections, and enhances aesthetics.

- Hard Coatings → Extend mold life and improve material release, reducing part defects.

Choosing the right mold type and surface finish ensures efficient production, reduced defects, and enhanced final product quality.

2. Trimming for Precision: The Key to a Perfect Part

Once a thermoformed part has been shaped, excess material must be trimmed, and holes, slots, and vents must be cut for functionality and assembly. The choice of trimming method affects accuracy, consistency, and production efficiency.

2.1 Trimming Methods: Pros and Cons

| Trimming Method | Best For | Pros | Cons |

| CNC Trimming (3-Axis/5-Axis) | High-precision, repeatability | Accurate (±0.015”), complex geometries | Higher cost than manual trimming |

| Die Cutting | Thin-gauge, high-volume parts | Fast, cost-effective | Limited to 2D cuts, not suitable for thick plastics |

| Hand Trimming | Low-volume, prototyping | Low setup cost | Inconsistent, operator-dependent |

2.2 Common Cut Types in Thermoforming

Depending on the application, thermoformed parts require different trimming techniques:

✔ Vertical Cuts → Used to remove excess material and create flanges for mounting.

✔ Horizontal Cuts → Adjusts wall height for precise part dimensions.

✔ Hole Cutouts → Required for fasteners, airflow, or access points.

For complex cuts or multi-surface trimming, 5-axis CNC trimming ensures repeatable, high-precision results.

3. Finishing Techniques: Elevating Thermoformed Parts

Finishing processes enhance the durability, functionality, and aesthetics of thermoformed parts. The right coating, texturing, or painting can make a functional part stand out as a high-quality product.

3.1 Finishing Options for Thermoformed Parts

| Finishing Technique | Best For | Benefits |

| Painting & Custom Coatings | Consumer products, branding | Custom colors, high-gloss/matte finishes |

| ESD Coating (Electrostatic Discharge Protection) | Electronics packaging, medical | Prevents static buildup, improves safety |

| UV Protective Coating | Outdoor, aerospace, automotive | Prevents yellowing, fading, and degradation |

| Sandblasting & Texturing | Industrial and consumer goods | Improves grip, scratch resistance, and aesthetics |

Applying the right finishing technique ensures thermoformed parts meet durability, branding, and safety requirements.

4. Thermoforming Tolerances & Quality Control

Even with high-precision tooling and finishing, thermoforming can result in minor dimensional variations due to shrinkage, thickness inconsistencies, or trimming variability. Implementing strict quality control measures is essential for consistent, defect-free parts.

4.1 Thermoforming Tolerance Guidelines

Thermoformed parts have looser tolerances than machined or injection-molded parts, but proper planning ensures parts remain within functional specifications.

| Feature | Tolerance (inches) |

| Formed Measurements (<6″) | ±0.015” |

| Medium Parts (6–12″) | ±0.025” |

| Large Parts (>18″) | ±0.030” + 0.002”/inch |

4.2 Quality Control Best Practices

✔ Pre-Production Testing – Verify mold accuracy, material shrinkage, and prototype performance.

✔ In-Process Monitoring – Inspect thickness distribution, mold fit, and trim accuracy.

✔ Post-Production Inspection – Use CNC measurement tools, visual inspection, and functional testing to ensure final part quality.

By maintaining strict quality control measures, manufacturers can reduce scrap, improve part performance, and maintain cost efficiency.

5. The Future of Thermoforming: Innovation & Sustainability

Thermoforming is evolving with advancements in automation, material science, and sustainability. Some of the latest trends include:

✅ 3D-Printed Tooling – Reducing mold costs and accelerating prototyping.

✅ Recycled & Biodegradable Plastics – Making thermoforming more sustainable.

✅ Hybrid Manufacturing – Combining thermoforming with CNC machining and 3D printing for complex, high-performance parts.

These innovations are making thermoforming more versatile, cost-efficient, and environmentally responsible.

6. Get Precision Thermoforming Solutions with RapidMade

At RapidMade, we specialize in high-precision thermoforming, ensuring your parts are manufactured with accuracy, efficiency, and superior quality. Whether you need custom tooling, CNC trimming, or advanced finishing, our engineering team is ready to help.

📞 Contact us today for expert thermoforming solutions!

📩 Email: info@rapidmade.com

🌐 Website: rapidmade.com

With RapidMade, you get a trusted partner in precision manufacturing, delivering cost-effective, high-performance thermoformed products—built to last.